Products

Columbia Precast produces reliable, durable concrete products for constructing infrastructure in the Portland/Vancouver area—and throughout the Pacific Northwest.

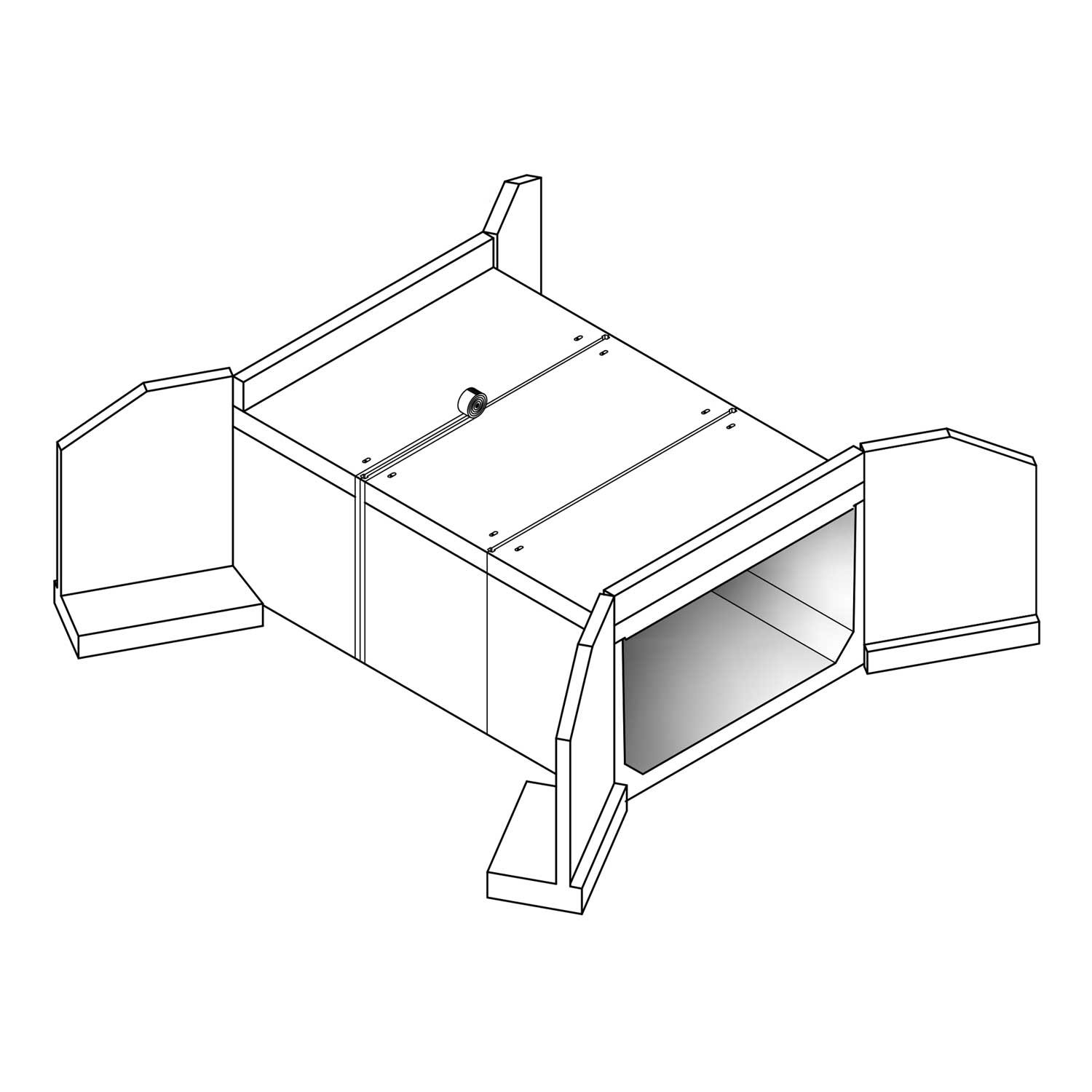

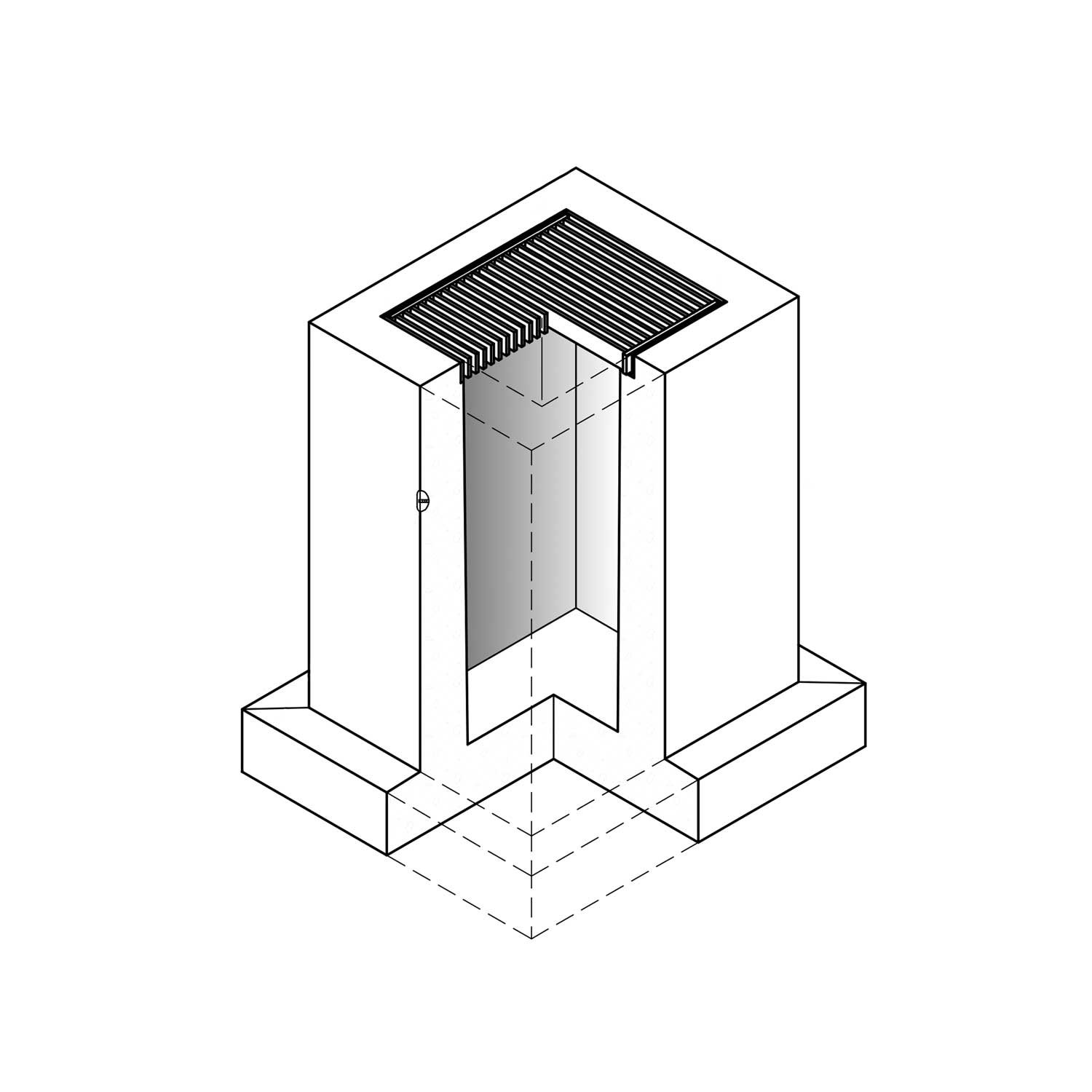

Browse our catalog of products to find specification drawings, and see the range of applications available for planners, civil engineers, and construction managers.

Looking for a specific part? Need an estimate? Contact us directly and we will gladly help. 360-335-8400